Driving The Future: Inside JBM Automotive's cutting-Edge Technology

Babra Auto India was established in 2019.JBM Automotive Industries his sister’s company.

QUALITY SYSTEMS:

We are implementing guidelines by the standard guidelines as a part of our quality drive to minimize defective output.

As per present standards, quality systems are adopted as per the design requirements and components. Tested raw material (as per quality Specification) is processed by reputed companies. The production process is controlled by a team of experienced and suitably qualified Quality Control Engineers.

At present, we are meeting the entire demand in terms of the quality of our principals. We are also gearing up to support their expansion plans. We have all types of measuring instruments, gauges, and fixtures as per the requirements of our principles.

MANAGEMENT PHILOSOPHY:

Technical : Technical is key to our future growth in our business.

Personal : Treating our employees the way we want to be treated ourselves.

Financial : Profitability through Quality & Productivity.

INFRASTRUCTURAL SETUP:

Currently, the Company’s production activities are located in Faridabad (Haryana) near New Delhi. The Company has sufficient: and (built and inbuilt) at plot no.20 a dhanda complex opp. Whirlpool(kelvinator), Gali. Industrial area, N.I.T. Faridabad 121001 (Haryana) which fulfills the current production requirements and undertakes any land of expansion in the immediate future. Land is available at the production site. Power load – 25 Kva (SEB)

PRODUCTION FACILITIES:

Capacity

50ton

30 ton

20 ton

250*550 CNC

250*350 CNC

1050*610*630 VMC

SPM Welding

Power Press

Mechanical

Mechanical

Mechanical

Mechanical

Mechanical

Mechanical

Mechanical

Make

Ratan

Ratan

Ratan

Ratan

Ratan

Ratan

Ratan

No. of Machines

01 Nos.

04 Nos.

05 Nos.

01 Nos.

01 Nos.

01 Nos.

01 Nos.

TOOL ROOOM FACILITIES

Types of Machine

Surface Grinder

Drill machine

Spot Welding

Lathe welding

Baler

Taping Machine

Welding Set

Milling Machine

Capacity

Standard Mark

Standard Mark

Standard Mark

Standard Mark

Standard Mark

Standard Mark

Standard Mark

Standard Mark

No. of Machines

01 Nos.

01 Nos.

02 Nos.

01 Nos.

01 Nos.

01 Nos.

01 Nos.

01 Nos.

TOOLING:

Height gauge – 1 Nos.

Mechanical vernier – 2 Nos.

Digital Vernier – 3 Nos.

Micrometer – 8 Nos.

Bor Gauge – 4 Nos.

Surface Plate – 1 Nos.

Man Power Operator – 12

Helper – 4

Supervisor – 1

Programmer – 1

Setter – 1

CNC Operator – 2

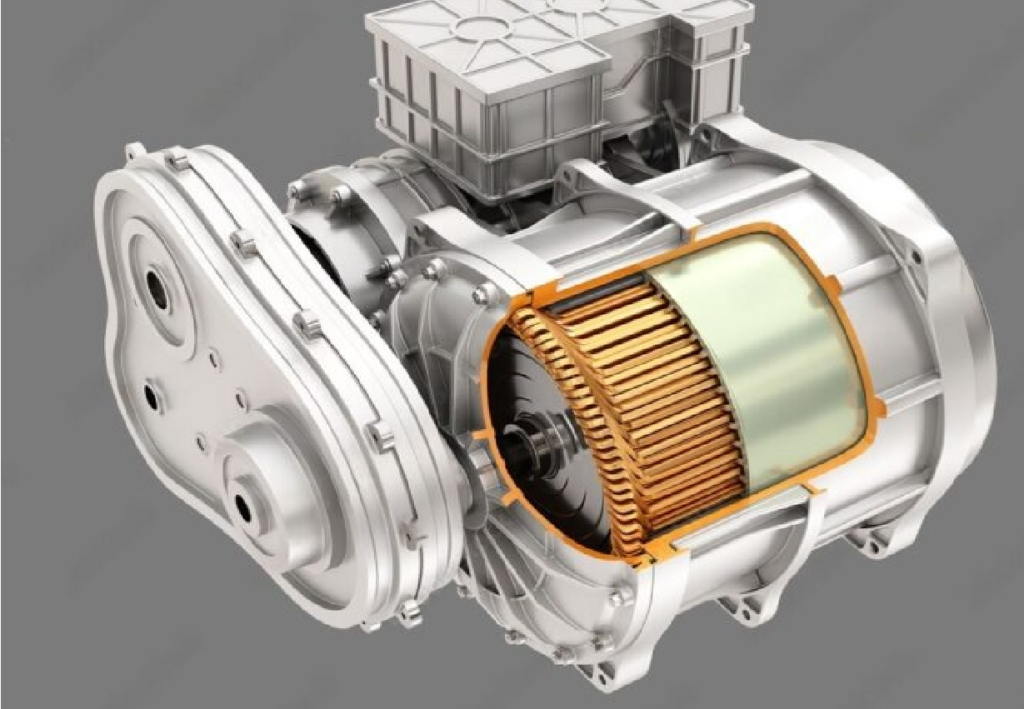

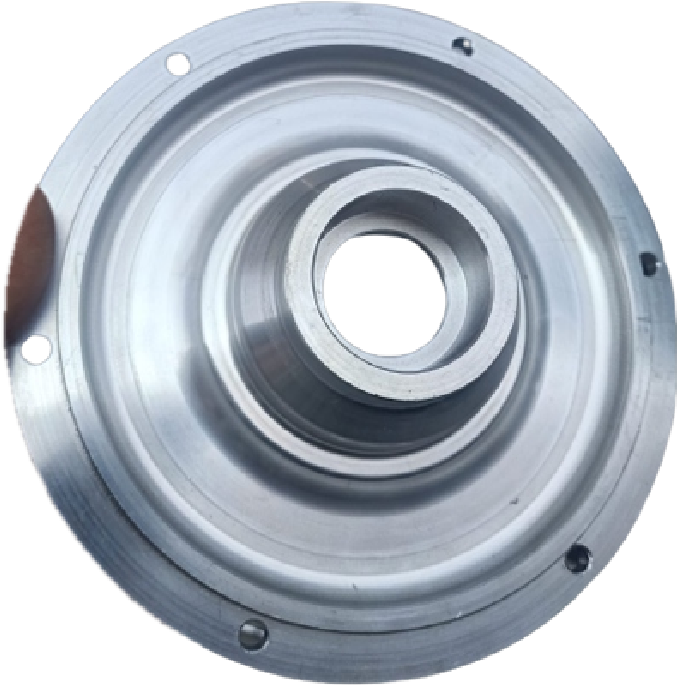

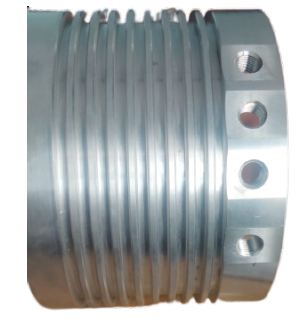

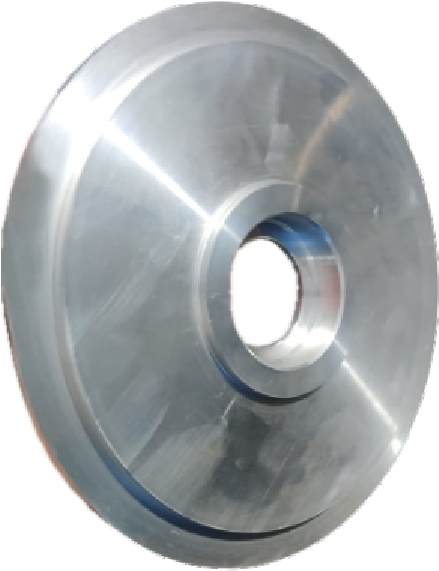

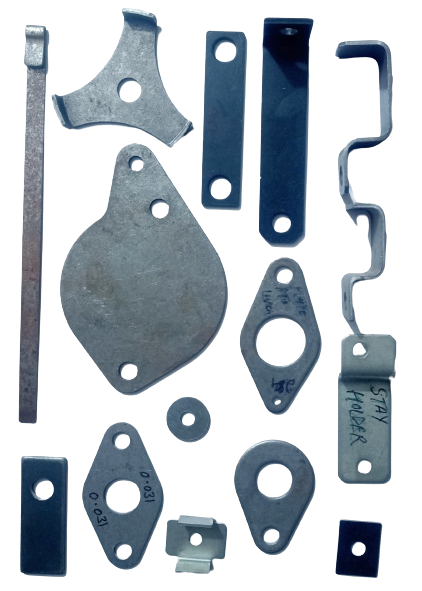

PRODUCT WE OFFER:

Backed by our in-depth domain expertise, we are engaged in successfully designing and developing a wide range of metal automotive components, precision automotive components, and automotive parts. Manufactured from superior-grade raw materials, these can provide efficient functioning at the client’s end. we offer :

OUR CUSTOMERS :

VISHWAS IND. AUTOTECH PVT.LTD.

MTC INDUSTRIES

SHREE JEE ENGG. WORKS

BBROS MOBILITY PVT. LTD

KFL INDIA PVT. LTD

SIETZ TECHNOLOGIES INDIA PVT.LTD

- DATUM TOOLS PVT.LTD

OEM CUSTOMERS :

HONDA

ESCORTS KUBOTA

- BBROS MOBILITY

Certificate of Registration

This is to certify that the Quality Management system of

JBM AUTOMOTIVE INDUSTRIES.

Plot.no-20 A, Dhanda complex, Industrial Area,-121001, Haryana, India

Is in accordance with the requirement of the following standard

ISO 9001:2015

(Quality Management System)

SCOPE

Manufacturing All kinds of Machining, Fabrication, and Sheet Metal Parts.

(IAF Code: 17)

Certificate Number: 060124019109

To Verify Certificate.Visit at:

www.arscert.com

www.uafaccreditation.org

www.iafcertsearch.org

CB-MS-3923

Initial Registration Date:06-JAN-2024

1st Surveillance Date :06-DEC-2024

2nd Surveillance Date :06-DEC-2025

Certificate Expiry Date :06-JAN-2027

Issued by ARS Assessment Private Limited

Managing Director

UAF Address: 400, North Centre Dr, STE 202, Norfolk, VA 23502, United States of America

This certificate remains the property of ARS and must be returned to ARS on Cancellation or suspension of the certificate validity of the certificate is subject to successful completion of surveillance audits. Further clarification regarding the scope of this certificate and the applicability of the standard may be obtained consulting the Organisation on info@arscert.com

WAREHOUSING, PACKAGING & TIMELY DELIVERY

Our spacious warehousing facilities enable us to safely store our range of finished products like filters, reserve tubes, spring sheets, lower spring sheets, and others. Further, we also have the facilities to ensure qualitative packaging for our range with proper labeling. This provides the complete safety of the products during the transit period.

All these facilities and our tie-ups with reputed logistic companies assist us in also meeting the prompt delivery demands of the consignments at the customers’ end.

QUALITY ASSURANCE

We are committed to manufacturing a qualitative range of metal automotive components, precision automotive components, and automotive parts for two and three-wheelers that successfully meet the demands of automotive applications.

The support provided by our quality checking unit assisted us in checking the involved process including the procurement of raw materials, the dimensional accuracy of the manufactured products, and the flawless functionality of the end product. Further, our quality checking unit is segregated into the following divisions:

- Inspection division: This department is well equipped with all the tools and equipment that are used for the inspection of the products at different stages of design and development.

- Processing division: Our processing division helps in the final inspection of the product before delivery of the end products to the clients.

OUR TEAM

The services of our qualified and dedicated team of engineers, machining experts, industrial designers, and others help us to achieve a positive growth rate in a short period. Their domain expertise enables us to achieve high production standards at every stage, which also helps us to deliver end products as per international quality standards.

In addition to this, our team members are well versed in the involved manufacturing processes, which help us in the production of the range as per the given specifications of the clients. They are also aware of the changing trends and emerging demands of the automotive industry, which assist them in manufacturing products as per the exact application requirements of our customers.

Looking forward to a long and fruitful relationship with you.

Thanks, Regards.

For: – JBM AUTOMOTIVE INDUSTRIES

(Jainpal choudhary & Boota Singh)